The HA is committed to minimising our environmental footprints and building resilience to the potential impact of climate change for our new and existing housing estates, as well as our office.

The HA endeavours to enhance the resilience and sustainability of our housing to cope with all kinds of environmental challenges. Over the past 20 years, we have been designing our buildings in a sustainable way, which empowered us to align with the global call for climate change mitigation.

Our estates are planned and designed with climate resilient features in pursuant of the prevailing guidelines, such as Urban Design Guidelines of Hong Kong Planning Standards and Guidelines. It categorically aims at alleviating different climate scenarios, such as urban heat island effects.

Apart from conserving the rain water for irrigation, our Zero Irrigation System (ZIS) also served as a de-centralised storage for rainwater. As the frequency of extreme weather conditions is expected to rise in the future, it is vital to implement measures to mitigate the impacts of rainstorm and flooding. For more details of the ZIS, please refer to the Case Study: Zero Irrigation System – The Water Conservation Innovation section.

Design with skylight combined with high volume low-speed fan at external area based on micro-climate studies to enhance the human comfort

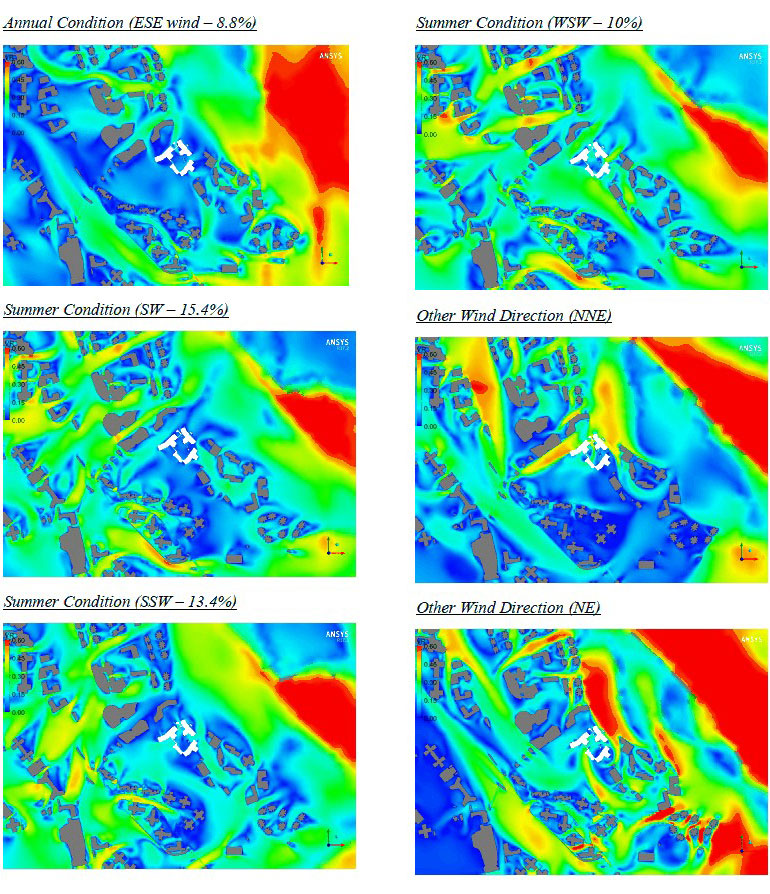

The HA takes sustainable design into the account in the planning and design of our new estates. Micro-climate studies and Air Ventilation Assessments (AVA) are applied to study the impact of various environmental factors, such as wind availability, natural ventilation, daylighting and shading, thermal comfort, as well as pollutant dispersion. We will leverage the results from the assessment and make suitable design which best responds to these environmental factors.

Conducted micro-climate studies in 32 on-going projects

Carried out Air Ventilation Assessments in 15 on-going projects

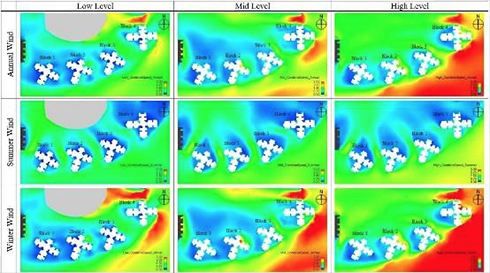

Analysis on low, mid and high zone outdoor wind environment

Air Ventilation Studies carried out for projects under design stage

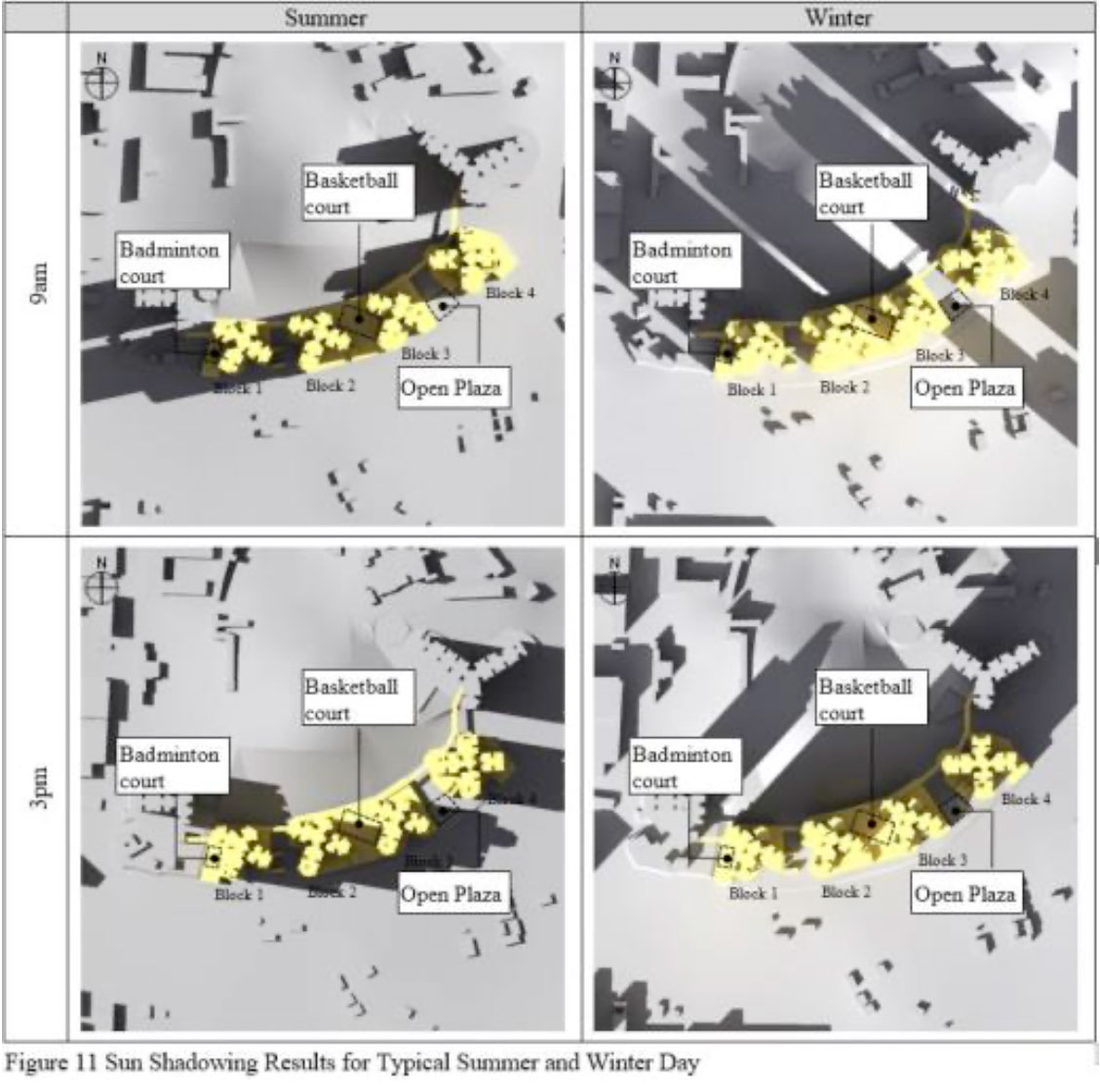

Sun shading study provides basis for planning and design of open space

To ensure we are in line with the Government’s Hong Kong Climate Action Plan 2030+, we have continued to apply the Carbon Emission Estimation (CEE) for all projects at detailed design stage. This year, we conducted CEE for seven projects. The estimation included carbon emission in the construction stage and throughout the whole lifecycle of the building, which allows us to better manage and understand our carbon footprint.

Reduced the estimated communal energy consumption for domestic block by about 29% compared with the baseline figure

Cement, a carbon-intensive material, is a widely used material in construction. As such, the HA has been exploring different greener alternatives of construction materials to replace the use of cement in our new projects. For example, we use granulated blastfurnace slag (GGBS) as a replacement material for cement in concrete for the manufacture of precast facades and staircases in domestic blocks, and cement stabilisation treatment to convert marine mud waste excavated from sites to useful backfilling material. The application of such alternatives can help reduce our carbon footprint in the construction stage.

We also explore the use of innovative materials and products which impose less impact on the environment. Examples include the introduction of B5 bio-diesel to all off-road construction machinery on site with the support from Hong Kong Construction Association and contractors. A trial of replacing river sand with manufactured sand was carried out. In the trial, we applied mortar consisting manufactured sand to vertical surfaces, the workability and performance of proposed specification achieved a satisfactory result similarly with traditional cement/ sand. Furthermore, the application of structural soil in On Tai Estate not only complies with the load-bearing requirements, but also promotes vegetation growth.

On green products, the Hong Kong Green Building Council (HKGBC) has incorporated the HKGBC Green Building Product Labelling Scheme, Construction Industry Council (CIC) Carbon Labelling Scheme, and the HA’s product certification scheme in the BEAM Plus credits of the BEAM Plus for New Building version 2.0. In this regard, we have updated our specification clauses meeting the assessment criteria of BEAM Plus for implementation in all our new works projects. We will continue to monitor the HKGBC Green Product Accreditation & Standards Scheme and, where applicable, revise our guide on green materials and products for maintenance and improvement work.

To enhance the environmental performance of contractors and reduce waste generation on-site, we have developed several standards to better manage our innovative and environmentally friendly practices. For instance, standardised-designed precast segment roof water tanks are applied in our new projects. We also established guideline for “Implementation of Precast Construction at Roof of Domestic Block” and implemented the precast acoustic balcony in the latest Modular Flat Design.

Use of PCCs reached 70%precast rate on plan at a typical floor of domestic block of suitable housing development

Construction productivity maintained a 6-day cycle for each typical housing floor

We have adopted the precast concrete components in common areas, including precast structural walls with concealed conduits, and precast lift shafts with pre-installed lift guide rails.

Besides, all of our contractors are required to adopt various green construction methods on site. The requirements have been stipulated in all building, demolition, piling and civil engineering contracts.

Technological advancement allows us to enhance the quality of our design and the efficiency of environmental preservation procedures. Throughout the years, we have continued to implement Building Information Modelling (BIM) for planning, design and construction of our housing projects.

Recently, the “reality capture” technology enables us to obtain surface characteristics and spatial information of an object, building or site in 3D, hence accurate digital representations can be created. The application of this technology was further extended to tree preservation in a project at San Kwai Street. We used laser scanning technology to capture a set of 3D point clouds of the existing trees and integrate them with the BIM model of the project. As a result, our architects can accurately visualise the proximity and disposition of the existing trees, allowing us to make well-informed estate design and preservation decisions.

Integrated use of BIM and reality capture for tree preservation studies (before (top) and after (bottom))

Target to apply to all projects in 2021

The integration of two software enables us to conduct a more holistic and accurate analysis based on the data we have, particularly in the feasibility stage. Detailed visual impact assessments, including ridgeline, vantage point and shadow analyses could be performed.

The Building Environmental Assessment Method Plus for New Buildings (BEAM Plus NB) provides us with an objective external assessment of the environmentally friendly features of our new buildings throughout their lifecycle. We strive to implement specification clauses meeting BEAM Plus assessment criteria in all new buildings and aim at achieving gold rating standard or above.

During the year, the following projects received the provisional assessment under BEAM Plus NB (Version 1.2):

| Project | Rating |

|---|---|

| Subsidised Sales Flats Development at Ma On Shan Road | Provisional Gold |

| Public Housing Development at Tai Po Area 9 and Public Housing Development at Chung Nga Road East, Tai Po | Provisional Gold |

| Subsidised Sale Flats Development at On Muk Street Phase 1, Shek Mun, Sha Tin | Provisional Gold |

10 projects registered & 3 projects awarded during the year

3D illustration of Subsidised Sale Flats Development at On Muk Street Phase 1

3D illustration of Subsidised Sale Flats Development at On Muk Street Phase 1 - 2

of building services installations in communal areas was 21.39 kWh/m2/Annum

The HA recognised the importance of effectively managing the use of energy, we strive to enhance the energy efficiency in our new housing estates. As such, we have implemented the Energy Management System (EnMS) in accordance with ISO 50001 for our projects since 2011 and planned to transit to the ISO 50001:2018 edition before August 2021. The transition enables us to better understand our energy performance, which would lead to a reduction of GHG emissions. Furthermore, we extended the scope of ISO 50001 to require contractors to implement this ISO standard, allowing us to have a more holistic approach in managing our energy consumption in different stages of construction.

To promote the use of renewable energy, we started installing grid-connected photovoltaic (PV) systems in new PRH projects since 2011 and joined feed-in tariff schemes launched by electricity supply companies. Thus far, our PV systems are designed to feed in electricity equivalent to about 1.5% to 2.5% of the building communal area’s demand.

Installed in 109 domestic blocks, with a total system capacity of 1010 kW

PV panels at On Tai and On Tat Estates

To support the Government’s initiative on promoting wider use of electric vehicle (EV), the HA has installed EV charging facilities in car parks of all new estates. For our new indoor private car parks, 30% of the parking spaces are equipped with EV charging facilities, while EV charging-enabling facilities (including electricity distribution boards, cables, conduit and trunking) are installed for the remaining 70% parking spaces and reserved for future installation of EV chargers.

The design of our new buildings follows the “Guidelines on the Design and Construction Requirement for Energy Efficiency of Residential Buildings” (the Guidelines) issued by the Buildings Department in 2014. Following the Guideline, we continue to explore opportunities of incorporating green designs into our new buildings and enhancing natural ventilation and environmental performance.

We also comply with the Building Energy Codes issued by the Electrical and Mechanical Services Department (EMSD) in new building projects to meet the energy efficiency requirements accordingly. 168 Certificates of Compliance Registration from the EMSD are received to show our compliance with the Building Energy Efficiency Ordinance.

To promote energy conservation for lift systems, energy efficient gearless lifts and permanent magnet synchronous motors are adopted in new buildings. Also, we introduced the regenerative power for lift systems using motors with power rating of 8kW or above in new projects.

Over the years, we have started replacing Compact Fluorescent Lamps (CFL) with LED bulkhead lights as standard lighting in communal areas of domestic blocks. We also adopted energy efficient LED Exit Signs and Directional Signs in new projects starting from 2019. Furthermore, two-level lighting system for barrier-free access in domestic and non-domestic blocks of new works projects are implemented in order to meet the illumination requirements. Environmental lighting controls using motion-sensors and push buttons were also applied at the communal areas of all domestic blocks.

Regular reviews have been conducted to ensure the effectiveness of our energy management measures. We are committed to aligning the design of our new projects with the mandatory requirements on Residential Thermal Transfer Values promulgated in the Buildings Department’s Practice Note.

Push button for two-level lighting controls (before (left) and after (right))

LED bulkhead

Smart meter monitoring and information display systems have been installed at the main entrance lobbies of new housing blocks. It provided our tenants with a dashboard to understand their monthly energy consumption information. Data on the consumption of electricity, gas and fresh water of the block in the same month last year are also shown in the system.

Dashboard showing the energy consumption of the building

Fresh water is consumed mainly in the construction process of new works projects, daily washing, flushing and irrigation. In this regard, we have implemented various measures in our new projects to conserve the use of water resources. For example, 6-litre single or dual flush water-closet suite was used in all new buildings to reduce flushing water consumption.

To apply the balanced ecological planning and design principles in new works projects, we have initiatives to add new vegetation and promote greening in new housing estates. We have planned all new estates with a greening ratio of at least 20%, with a target of 30% for sites area greater than two hectares. Moreover, we also adopted a tree planting ratio of not less than 1 tree per 15 flats for new housing development.

During the year, we provided hydroseeding, planting or other appropriate green treatments to newly formed slopes, including the slopes in Fung Shing Street, Texaco Road, Tung Chung Area 27, etc. To put these principles into practice, we held briefing and debriefing sessions, as well as site visits for our contractors. We also coordinated with the Development Bureau to establish guidelines and provisions for facilitating our communication with contractors.

At Fai Ming Estate which is located near an unspoiled valley in Fanling, we designed an ecological garden to preserve the wildlife near to the housing site. From ecological survey and assessment carried out during the design stage, bats were found underneath the culvert while butterflies, birds and some local species were found from the nearby watercourse, grassland and woodland. To minimize the impact on these wildlife species, we adopted mitigation measures including providing a buffer zone with no development for protecting the watercourse and the bat roost; and a transition zone designed as an ecological garden with native trees and shrubs for providing the ecological resources best for species from the woodland and shrubland habitats.

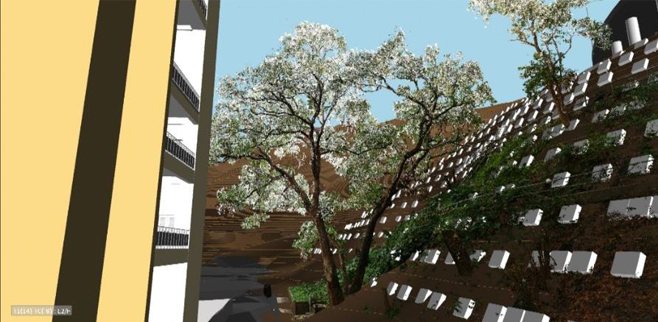

Meanwhile, we are developing a prefabricated modular system to make planting trees at ground level and podium easier and more efficient. Currently, we are exploring to use more of pre-grown vertical green panels at appropriate projects, allowing us to expand the green coverage and create “instant greening” effects.

A newly formed slope with hydroseeding and planting in Fung Shing Street

Vertical greening is more widely employed to achieve the green ratio

The ecological garden in Fai Ming Estate serves as a transition zone to provide the ecological resources for species from the woodland and shrubland habitats

To optimise the use of resources, felled trees are recycled at some of our sites. We setup on-site shredding and composting to recycle felled trees to mulch for landscaping use. Meanwhile, some felled trees are cut into wood chips for composting with food and garden waste.

We have continued to promote local residents and community to participate in our greenery work. Through the Action Seedling programme, tenants are invited to participate in the gardening and planting at our designated planting area for recreation and education purposes.

Action Seedling at Long Ching Estate

Action Seedling at Long Ching Estate

Buildings located close to the road will be impacted by road traffic noise. As such, we used different types of noise mitigation measures, including acoustic windows, acoustic balconies, architectural fins and noise barriers, etc., in different projects to suit the site-specific characteristics. Moreover, the design of second-generation acoustic precast balconies features an additional sliding screen in front of the balcony doors, noise absorptive material in the balcony wall and ceiling, and inclined panels along the parapet. All these designs are effective in mitigating the traffic noise nuisance and improving living experience of the residents.

To align our practice with the Development Bureau’s implementation plan, four types of Exempted Non-Road Mobile Machinery in HA’s construction sites with greater than $200 million estimated value have been phased out. Filters have also been installed in our contractors’ plants and machinery for removing air pollutants.

A risk assessment in accordance with ISO 31000 Risk Management System was conducted for the construction of new buildings. During the assessment, about 2,300 building materials used in architectural, building services, geotechnical engineering, landscaping works and structural materials were assessed. The application of this system enables us to monitor and enhance the quality of building materials as well as to understand their potential impacts on the environment.